ID Grinder Rebuilding and Upgrades

- BRYANT GRINDERS

- HEALD GRINDERS

- KOYO GRINDERS

- OKUMA GRINDERS AND MORE

Our expertise in ID grinder operation makes GCH Machinery a sought-after resource when companies need to improve their grinding operations. GCH Machinery can rebuild your machine tool or remanufacture it to better than OEM standards and guarantees the work with a one-year warranty.

Looking to incorporate your ID grinder machine into a cutting-edge grinding cell? GCH Machinery provides turnkey solutions to manufacturers who wish to automate their grinding operations.

We also keep durable, cast iron ID grinder bases in stock, ready for remanufacturing or rebuilding to your specifications.

Every grinding machine we rebuild or upgrade is tested and approved using the customer’s actual production parts. Our ID grinder expertise and dedication to customer satisfaction ensure you get the machine that meets your needs.

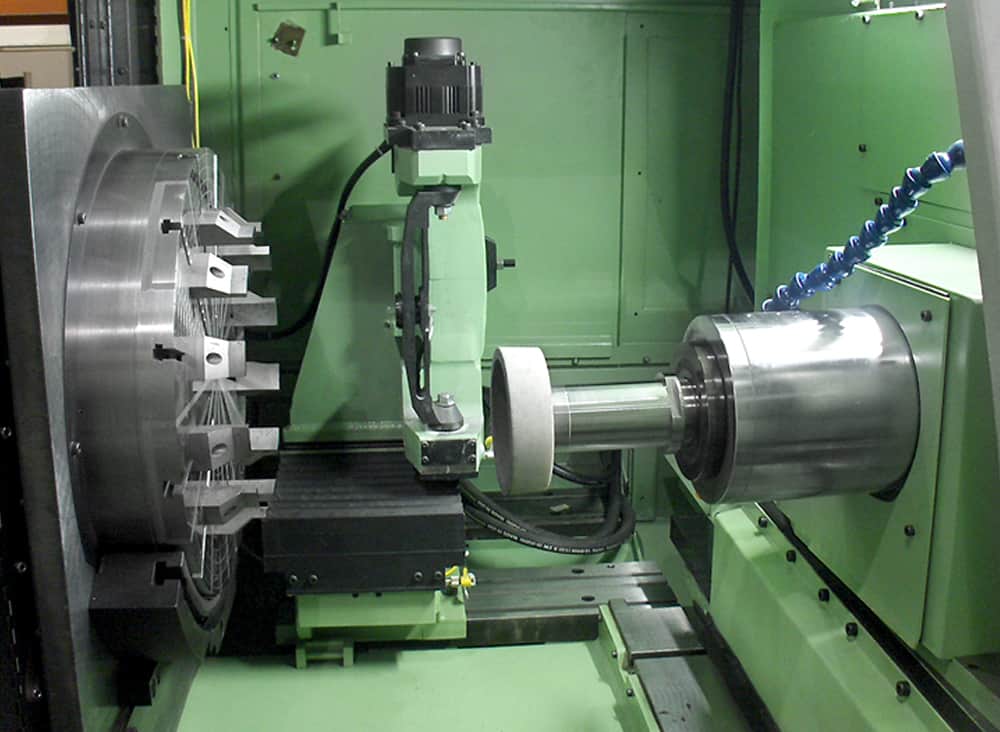

Click the images below to view full-sized photos of our rebuilding and remanufacturing capabilities for ID grinders.

What is ID Grinding?

ID grinding, also known as internal grinding, inside diameter grinding, inner diameter grinding, or bore grinding, is a precision machining operation in which the workpiece is held in place by a collet that also rotates the object in place. As with other types of cylindrical grinding, the workpiece and the grinding wheel rotate in opposite directions.

What is an ID Grinder Used for?

ID grinding is well-suited for removing a wide range of materials from straight, formed, and tapered workpieces.

Regardless of the type of workpiece, our remanufactured and rebuilt ID grinders are known for their capability to hold ultra-tight tolerances on bores, angles, and faces. Our attention to detail ensures that every ID grinder is hand scraped and machined to better-than-new condition. Grinder rebuilds from GCH Machinery play an integral role in a wide range of operations, ranging from job shops to high-production manufacturers.

We also remanufacture and rebuild OD grinders, as well as universal ID/OD grinder models.

Learn more about our machine tool rebuilding and remanufacturing services for Bryant, Heald, Koyo, Okuma and other ID grinders.

Contact Us

Request for Quote

Fields marked with an asterisk are required.