Expert Remanufacturing Services that Exceed OEM Quality

Are you saddled with an older grinding machine that is unreliable, costly to maintain and reliant upon experienced older operators, who may or may not be around in years to come?

Are you considering your options – whether to have the machine tool rebuilt or entirely remanufactured? Having your grinding machine remanufactured can provide performance advantages that aren’t available with a simple machine tool rebuilding.

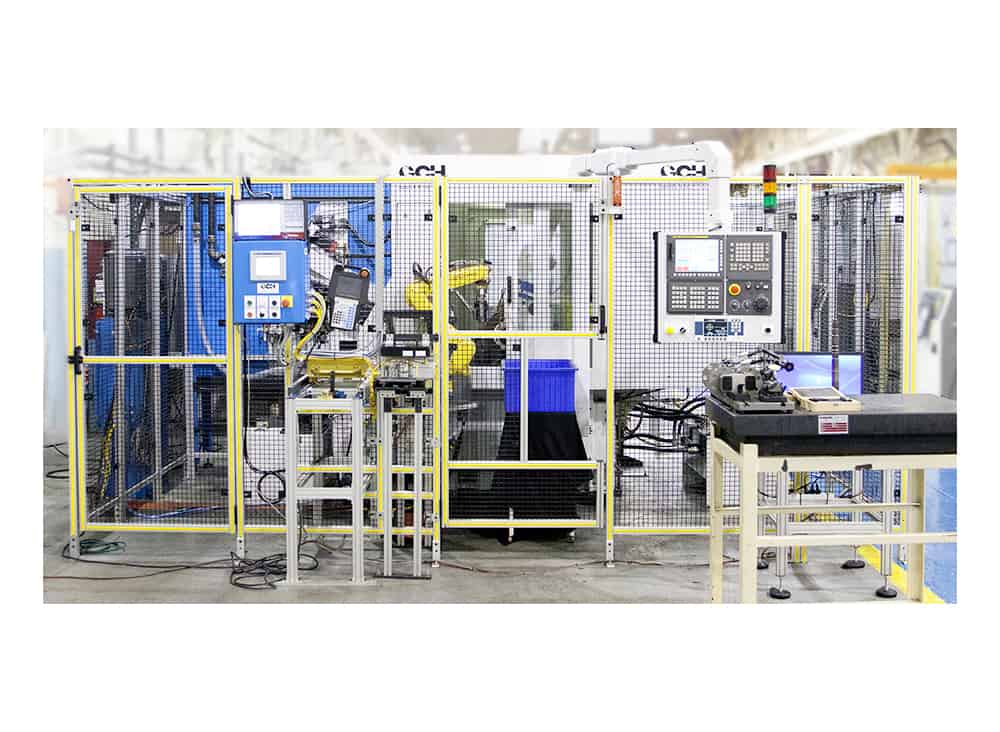

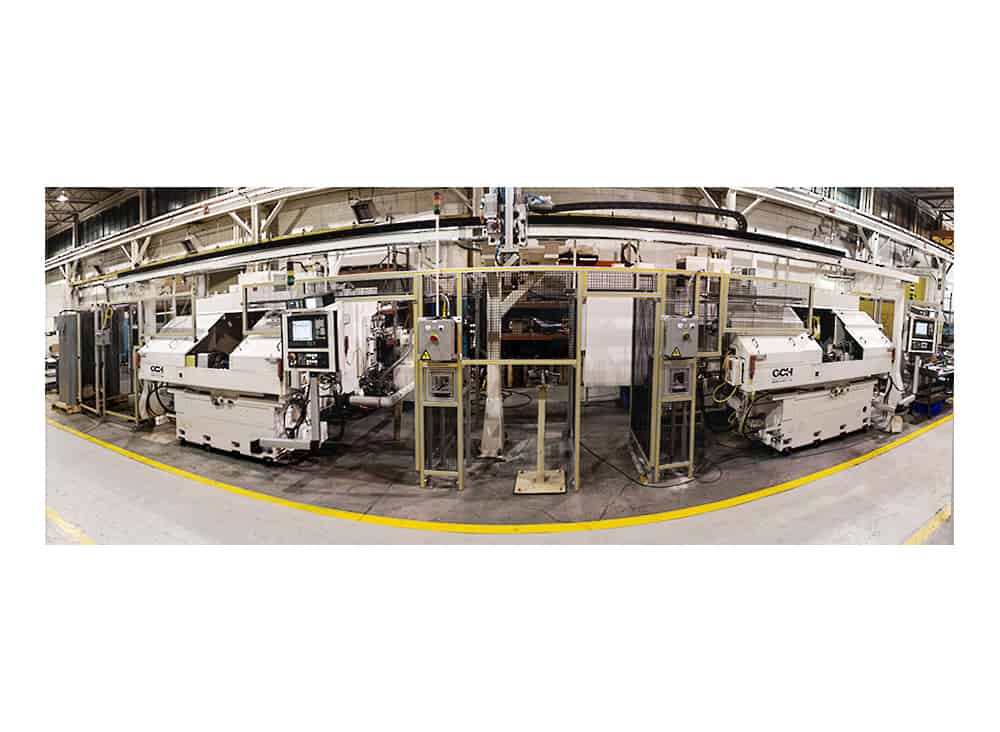

Click the images below to view full-sized photos of our remanufacturing capabilities.

GCH Machinery has both the machine tool remanufacturing experience and know-how to take your older machine and restore it to the original OEM specifications (and beyond) using the most modern mechanical and electronic technology available. The end result is a high-precision machine or grinding cell that has been remanufactured to your exact requirements, fully supported by our GCH Machinery technical staff.

In addition to remanufacturing services, GCH also offers many grinder upgrades and grinder accessories.

Before anyone touches your machine, we’ll meet with you to go over your requirements in depth. Our team will offer suggestions to allow you to get more production out of your grinding machine. If warranted, we’ll examine your grinding application to see where processes can be honed and improved. Our employees are known for their ability to come up with creative solutions to your manufacturing challenges.

Nine reasons for selecting GCH Machinery for your grinder or machine tool remanufacturing or rebuilding:

COMPETENCE

Our key personnel have over 260 years of direct employment with grinder companies in the areas of engineering, manufacturing, assembly and field service.

LEADERSHIP

A single point project manager will be assigned to actively monitor all phases of your machine tool remanufacturing or rebuilding project from start to installation. Your assigned project manager provides time lines to track each milestone.

INVENTORY

Access to the world’s largest inventory of new spare parts and components for centerless, ID, OD, double disc and surface grinders, housed by our sister company GCH Tool Group.

INGENUITY

Access to GCH-exclusive upgrades engineered specifically to optimize your grinder’s performance

WORKMANSHIP

Old-world craftsmanship, including hand scraping of components for better accuracy, flatness and oil retention, and better appearance.

NEAR-ZERO DOWNTIME

An exclusive exchange program that will allow us to provide you with a substitute machine while yours is being remanufactured.

QUALITY

All remanufactured equipment comes with a global warranty standard.

KNOW-HOW

Experience working on virtually every make and model of grinder available worldwide, plus expertise in remanufacturing and rebuilding a variety of machine tools, from lathes to mills.

DOCUMENTATION

The documentation you will receive with your grinding system is far beyond what most companies provide. All appropriate documents are supplied to you in both electronic and printed form, and include: a 100% new bill of materials; CE, GOST or other certifications; step-by-step setup instructions; safety features and standards; all electrical schematics and BOM; required maintenance; recommended spare parts list; floor plans; layouts; and software programs

We have a proven machine remanufacturing process implemented on over 1,000 machines located around the world. When we renew a grinder, we do it right.

Here’s what’s included with our remanufacturing services:

- All ways, slides and moving surfaces are precision hand scraped and flaked.

- All spindles are ceramic coated or chrome plated and ground.

- New precision-scraped Filmatic bearings that are matched to the new spindle surfaces

- All bearings, roller, ball and angular contact are replaced with new matching precision sets

- New hydraulic valves

- New steel pipes, hydraulic hoses and fittings

- New hydraulic pumps, filters and motors.

- New electrical, motor starter and fuse blocks

- New panel disconnects, wiring and transformers

- New NEMA 12 electrical enclosures

- New SLC, PLC and CNC controls

- New control console color CRT and push buttons (option)

- Complete AutoCAD schematics (electrical, hydraulic, pneumatic)

- New auto lubrication controls, new lube blocks, steel lines and fitting

- New motion control devices, servos and steppers

- New precision ground ball screws and nuts

- New grinder tooling

- New automation for loaders and unloaders

- New gages for in process and post process

- New auto wheel balancers

- New constant surface footage

- Special load monitoring devices

- Choice of color-customer selection

- Completely re-tooled set-up and SPC and CPK run-off on your part

- Complete turnkey package

- Global warranty standard

We can customize our standard process to meet your needs. Learn more about our remanufacturing and rebuilding capabilities for centerless grinders, surface grinders, double disc grinders, ID grinders, OD/cylindrical grinders and Microcentric grinders.

Contact Us

Request for Quote

Fields marked with an asterisk are required.