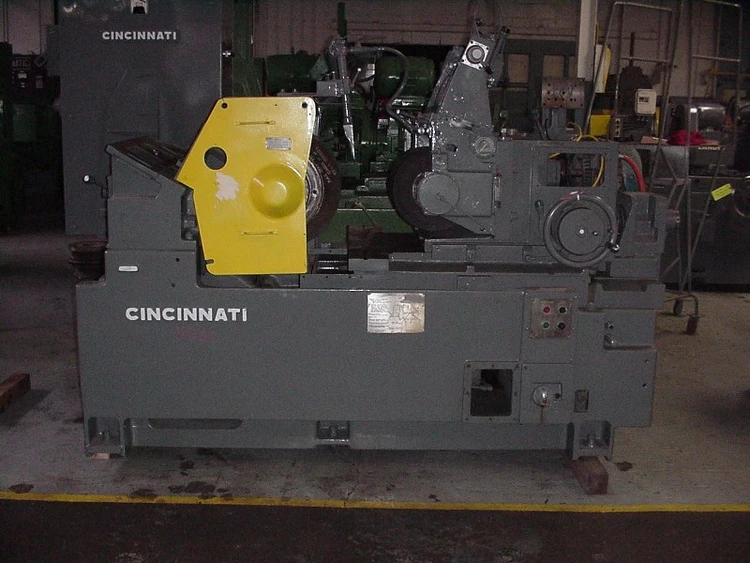

#325-12 Cincinnati Centerless, Model DE, Hydraulic Profile Truing Both Wheels, Outboard Support on Reg. Spindle, 24" G.W., 25 HP

325-12 CINCINNATICENTERLESS GRINDER

PRIVATE S/N 6M12H6M-3Year: 1963tc�\l 1 S/N 6M12H6M-3����Year\: 1963

STANDARD CATALOG SPECIFICATIONS

CAPACITY (Work rests or bar grinding fixtures are not

standard equipment.)

Standard thru feed in feed work rests........ 1/2 to 3 dia.

Maximum work diameter......................... 6

(Depending on which work rest is ordered)

BAR GRINDING FIXTURES

Type V - Solid bars...................... 1/16 to 1 1/2 dia.

Type V - Modified for light walled

or other similar material....... 1 1/2 to 2 1/2 dia.

Type C - Lengths up to................... 24 ft.

Solid bars...................... 1/2 to 2 dia.

Hollow tubes.................... 1/2 to 4 dia.

WHEELS (Not included in price)

Grinding wheel.................12 Hole, 8-12 Widths

......................................24 Max. dia., 16 Min. dia.

Regulating wheel...............6 Hole, 8-12 Widths

......................................14 Max. dia., 10 1/4 Min. dia.

GRINDING WHEEL SPINDLE

PRIVATE High grade alloy steel, heat treated, titanium dioxide coated and ground. Filmatic bearings self-adjusting for variations in load with plain thrust bearing in center. Automatic circulating lubrication under pressure.tc�\l 1 High grade alloy steel, heat treated, titanium dioxide coatedand ground.� Filmatic bearings self-adjustingfor variations in load with plain thrust bearing in center.� Automatic circulating lubrication underpressure.

REGULATING WHEEL SPINDLE

PRIVATE High grade alloy steel, heat treated, titanium dioxide coated and ground. Two piece bronze front and rear bearings, anti-friction radial and thrust bearing on end. Automatic pressure lubrication.tc� \l 1 High grade alloy steel, heattreated, titanium dioxide coated and ground.�Two piece bronze front and rear bearings, anti-friction radial andthrust bearing on end. Automatic pressure lubrication.

REGULATING WHEEL SPEEDS

Number..............................Infinite

Range...............................60 cycle: 11 to 300 RPM

......................................50 cycle:12 to 315 RPM

Low range........................... 60 cycle: 11 to 56 RPM

.........................................50 cycle:12 to 59 RPM

High range.......................... 60 cycle: 56 to 300 RPM

..........................................50 cycle:59 to 315 RPM

GRINDING WHEEL DRIVE

Enclosed motor on end of machine......... 25 HP

Constant speed, NEMA dimensions.......... 50 - 60 cycle, 3 phase

208 or 575 single; 230/460 dual voltage

AC drives grinding wheel only.

Power transmission....................... 8 V-belts

REGULATING WHEEL DRIVE

Motor mounted on upper slide........ 60 cycle: 2 HP @ 1200 RPM

...................................................50 cycle:2 HP @ 1500 RPM

Constant speed, NEMA dimensions..... 50 or 60 cycle, 3 phase

...................................................208 or 575 single; 230/460 voltage AC

Power transmission.................. 8 V-belt chain

Speed changes...........Variable pitch sheaves and gear shift

CUTTING FLUID EQUIPMENT

Individual motor driven cutting fluid pump capacity 30 GPM

Cutting fluid tank capacity.............. 75 gallons

WHEEL TRUING

PRIVATE Independent truing units for each wheel. Hydraulic diamond profile truing for grinding and regulating wheels. Diamond not included as standard equipment.tc� \l 1 Independent truing units for eachwheel.� Hydraulic diamond profile truingfor grinding and regulating wheels.�Diamond not included as standard equipment.

SIZING ADJUSTMENT

PRIVATE Accurate adjustment of regulating wheel slide by in feed hand wheel graduated in fifty millionths of an inch.tc� \l 1 Accurate adjustment of regulatingwheel slide by in feed hand wheel graduated in fifty millionths of an inch.

FLOOR SPACE WEIGHT

Floor space.............................. 95 1/4 x 140 3/8

Weight...................................15,500 lbs.

PRIVATE EQUIPMENT FEATUREStc� \l 2 EQUIPMENT FEATURES

Hydraulic profile truing on grinding wheel.

Hydraulic profile truing on regulating wheel.

Outboard support (regulating spindle).

Attached electrics.

Specifications are deemed accurate, however, subject to verification or prior sale.

All exchange units/returns must be shipped within 30 days. All exchange units/returns must be shipped using DDP terms - Grinders Clearing House, Inc. dba GCH Machinery, is not responsible for any customs formalities or shipping costs.

If Grinders Clearing House, Inc. dba GCH Machinery does not receive exchange/core unit back within30 days, GCH will invoice FULL replacement cost (OUTRIGHT Cost) to customer.

We use cookies to improve your experience. Privacy Policy.