GCH Machinery is well known for its remarkable ability to turn older grinders into modern turnkey grinding system marvels. With engineering and production teams who are passionate about grinders, and a company philosophy that encourages innovation, excellence and ingenuity, it’s no wonder that customers are amazed by the dramatic transformation of their machine tools. Have we piqued your interest? Read more to learn about what goes on behind the scenes when GCH Machinery takes on your grinder remanufacturing project.

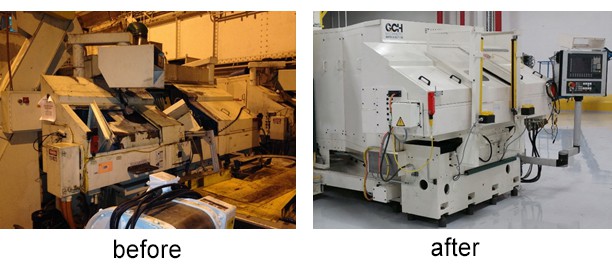

Toyoda OD grinder for a large multinational automotive maker

Part: Shafts for a new automotive transmission

Engineers from a global vehicle manufacturer approached GCH Machinery about remanufacturing an “orphaned” Toyoda OD grinder from the mid-1990s. The warehoused grinder had been re-assigned to a new production line for a series of vehicle transmission shafts. After careful review of the application, the GCH Machinery team concluded that a number of fixes and upgrades would turn this old grinder into a robust, modern grinding cell. Mechanical, hydraulic, pneumatic, lubrication, cooling and gaging systems were studied, with GCH determining that a complete overhaul of these systems would be required. Controls would be updated to Siemens 840D, known for flexibility, compatibility and innovation.

In just six months, the grinder was completely stripped to its base, all components were replaced, new tooling was added and state-of-the-art electrical and lubrication systems were installed. In addition, GCH added a number of upgrades, including a flagging system and an in-process gage to inspect 100% of parts.

This same automotive manufacturer has continued to work with GCH Machinery to update and bring back into service dozens of its warehoused grinders.

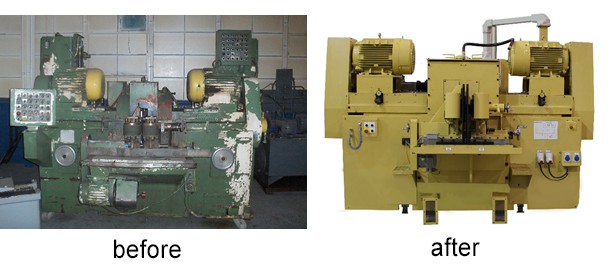

Gardner double-disc grinder for an international bearing company

Part: 4” bearings (face grinding)

Known for its outstanding technology, superior quality and exceptionally innovative spirit, a well-respected global bearing manufacturer contacted GCH Machinery to remanufacture one of its warehoused double-disc grinders. The grinder, vintage mid-1980s, was headed toward a central Asian bearing production line and needed a full remanufacture to meet the needs of this quality-conscious company.

GCH Machinery’s first task was to examine the grinding application and requirements to look for ways to improve the double-disc grinding process and then to assess exactly what would turn this piece of equipment into an advanced grinding machine.

Next came a redesign of the double-disc grinder’s mechanical, hydraulic, pneumatic, lubrication, cooling and gaging modules. A number of machine upgrades, exclusive to GCH Machinery, were added, including a new servo infeed to provide more accurate movement of the slides, and a new servo dresser to simplify machine structure and improve surface finish of the part. New THK slides were added to improve quality of the work part and reduce machine downtime and vibration.

What was delivered to the bearing manufacture was a state-of-the-art machine that exceeded OEM specifications and could hold a less-than-one- (1) micron tolerance.

Are you saddled with an older grinding machine? Learn more about GCH Machinery grinder remanufacturing by reading about our Remanufacturing Services or visiting our Before and After page.