Computerized Numerical Control (CNC) grinding machines or grinders are a type of machine that allows part machining to be carried out fully automatically. In other words, CNC grinding machines operate automatically with little intervention from a machine operator.

One of the things that must never be compromised during the grinding process is precision. High precision is an essential aspect of manufacturing. Precision grinding helps to increase the efficiency of a manufacturing process as it helps in producing parts with very tight dimensional tolerances and reduces the need for rework. CNC machines are especially important for engineering, electrical, medical, aerospace and other industries where there is minimal room for error because CNC grinders follow programmed instructions to produce precise parts.

This article contains all you need to know about CNC grinding machines, how they work, their benefits and how GCH Machinery can remanufacture and upgrade your old machines into high-performance CNC grinders.

Understanding CNC Grinding Machines

CNC grinding removes materials as they come in contact with the surfaces of the workpieces using a high-speed abrasive wheel as the cutting tool. This wheel rotates in place while the part or workpiece attached to the machine table moves in the X-, Y- and Z-axis.

Types of CNC Grinding Machines

There are several types of CNC grinding machines, and each type uses different techniques to produce parts. Let’s take a look at seven types of CNC grinding machines:

1. Surface Grinders: This process produces a flat, smooth surface on a workpiece. Surface grinder does this by using a rotating abrasive wheel to remove material from the surface of a workpiece.

2. Cylindrical Grinders: Cylindrical Grinders are used to grind the external or internal surface of a cylindrical workpiece to produce precise cylindrical shapes and tolerances.

3. Precision ID & OD Grinders: ID/OD grinders can grind either the inside or outside of a hollow cylinder without needing to remove the part from one machine and set it up a second time. Precision ID grinders can grind tapers, steps, contours and grooves both inside and outside a hollow round piece.

4. Centerless Grinders: Centerless grinders do not hold workpieces by a spindle, unlike centered grinders. Instead, the workpiece is secured between two rotary grinding wheels. This type of grinder allows for many parts to be processed quickly.

5. Center Hole Grinders: Center hole grinders are used to grind center holes into the products. This is a must for industries where misaligned centers can not be tolerated.

6. High Precision Rotary Grinders: High precision rotary grinders have a rotary table at the base, which helps the grinding wheels to effectively process workpieces along circular surfaces or edges as the workpieces rotate with the table during operation.

7. Double-Sided Fine Grinders: As the name already implies, this grinder grinds both sides of the workpiece simultaneously. These grinders come with both upper and lower discs or plates, which are used for grinding at the top and bottom surfaces, respectively.

The Benefits of CNC Grinding Machines

There are many advantages of using a CNC grinding machine, including:

- Improved Precision and Consistency: Since CNC machines are fully automated, program it to your desired specification, and watch it produce your parts with precision. This reduces the loss of materials due to waste and products not meeting the desired specification.

- Enhanced Efficiency and Productivity: Did you know that CNC machines can work all year round? This means you can meet your customers’ increasing demands without any downtime.

- Flexibility and Versatility: CNC grinding can be used for different materials such as metals, ceramics, aerospace alloys, hardened alloys, tool steels and more.

Remanufacturing and Upgrading Old Machines into CNC Grinders

As grinders age, they wear out, produce non-precise parts and break down frequently. And since old grinders are manual, unlike CNN machines which are fully automated, inconsistencies in grinding outcomes are common. The good news is that older grinders can be remanufactured or upgraded into CNC grinders with latest advancements.

Some of the benefits of remanufacturing or upgrading include:

- Less environmental impact

- Reduced downtime

- Improved performance and reliability

- Compliance with industry standards and regulations

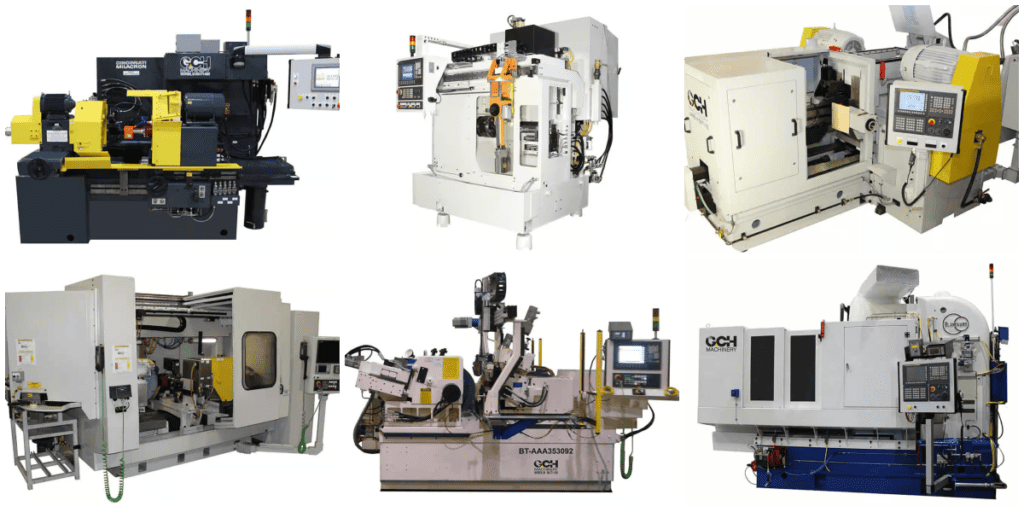

GCH is an expert in grinder remanufacturing and upgrading services. We remanufacture and rebuild leading grinding machinery brands, including Cincinnati, Blanchard, Heald, Besly, KMT, Okuma, Koyo, Springfield, Brown & Sharpe, Landis, Toyoda, Bryant, Gardner and more.

Choose GCH Machinery for Grinder Remanufacturing and Upgrading

GCH Machinery has both the experience and know-how to upgrade your old grinder to a world-class CNC grinding machine. We have been in the grinding machine business for over 50 years, so when we say we can transform your old grinder, we can!

One of the good things about CNC machines is its automation. Human errors and inconsistent parts will become history because its strength is in doing the same thing repeatedly and accurately.

Contact GCH Machinery today to remanufacture and upgrade your old grinder to improve its precision and efficiency.