In precision grinding and machining, Okuma is recognized for its top quality and precision. However, even the most durable machines wear down over time, affecting their precision. Businesses face a choice: replace their machines or opt for remanufacturing. This article discusses the benefits of Okuma grinder remanufacturing, a process that not only restores machines to their original precision but also maximizes investment returns and supports environmental sustainability.

Why Remanufacture Your Okuma Grinder?

Remanufacturing an Okuma grinder is a cost-effective, eco-friendly method to prolong your equipment’s life. Let’s look at some of the benefits of remanufacturing Okuma grinders in detail.

Cost-Effectiveness

Remanufacturing an Okuma grinder offers notable cost savings over buying new. It involves replacing worn or old parts with new ones at a much lower cost. This financial advantage allows businesses to redirect funds to other important areas.

Preserving Machine History

Preserving a machine crucial to your operations adds value. Familiarity keeps workflows smooth and eases the learning curve for new team members. Such continuity in using machinery boosts productivity and improves bottom-line results.

Environmental Sustainability

In an era where environmental awareness is crucial, grinder remanufacturing offers a greener option than buying new machines. By avoiding landfills, companies that opt for remanufacturing lessen their environmental impact, promoting a more sustainable future.

Extended Machine Lifespan

Remanufacturing prolongs the life of Okuma grinders by adding preventative maintenance and thoroughly inspecting and upgrading essential components to counteract wear and prevent future problems. This not only brings machines back to top performance but often surpasses their original lifespan, boosting their reliability and efficiency for precision machining.

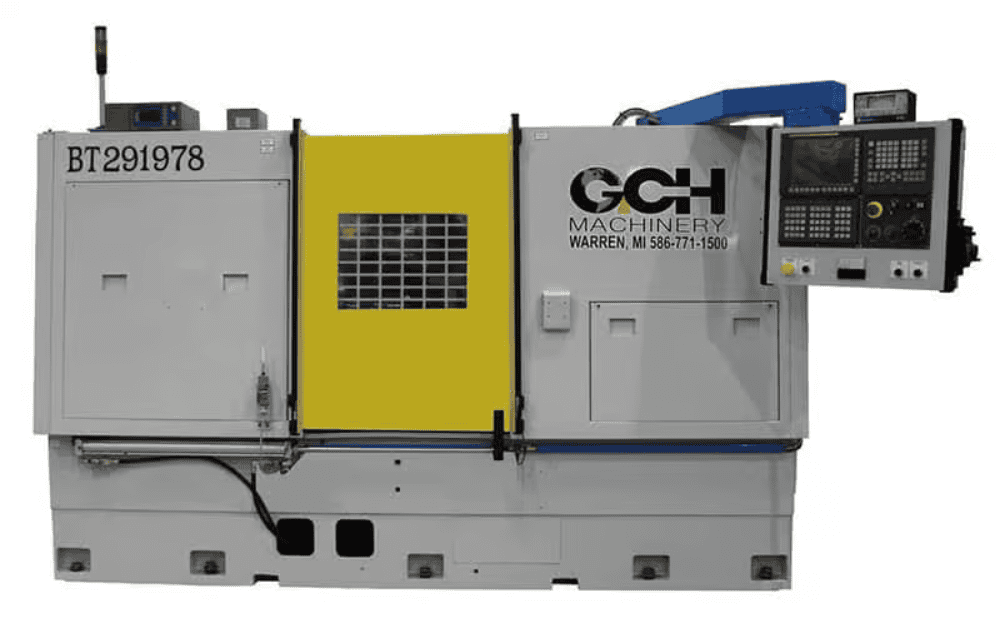

The Okuma Grinder Remanufacturing Process at GCH Machinery

GCH Machinery excels in remanufacturing Okuma grinding machines through a detailed process focused on precision, efficiency and quality.

Detailed Inspection

Every Okuma grinder that comes through GCH Machinery’s facility undergoes a meticulous inspection. This step is critical for identifying the extent of wear and tear. Component wear is measured, and potential trouble areas are flagged for the next stage of the process.

Component Replacement

Worn parts are replaced with either genuine Okuma components or OEM-approved equivalents. This commitment to using high-quality parts ensures that the remanufactured grinders will meet the high standards of performance and reliability that Okuma is renowned for.

Subassembly Refurbishment

The skilled team at GCH Machinery works on the ways, spindles, shafts and bearings with precision techniques that restore them to their original condition. These subassemblies are crucial to the core functionality of the grinder, and their refurbished state is key to a successful remanufacture.

System Calibration And Testing

One of the final stages involves extensive testing and calibration of the machine systems to ensure that the remanufactured grinder operates within the original manufacturing specifications. Stringent testing protocols guarantee the quality and precision of the finished product.

Installation

After successful remanufacturing, GCH Machinery delivers the Okuma grinder back to your facility where it is installed and integrated into your production line. Expert technicians handle the installation to make the process as seamless as possible.

Training And Support

GCH Machinery provides comprehensive training for your staff on the remanufactured machine, ensuring they are proficient in using the upgraded equipment. Ongoing technical support is also available, providing peace of mind and assistance as your team adapts to the high-performance remanufactured grinder.

Benefits Beyond Restoration: Optimizing Performance

The remanufacturing process for Okuma grinders not only restores but can enhance performance by upgrading control systems for better user experience and adding automation to increase productivity and efficiency.

Upgrading Control Systems

Upgrading an Okuma grinder’s control systems boosts its functionality. With modern controls, operations are more efficient, flexible and user-friendly. This update leverages recent technological advancements, keeping the grinder competitive in your operations.

Incorporating Automation Features

To meet demands for faster production and efficiency, automation can be integrated into the remanufacturing process. This not only saves time but also minimizes errors, making the grinding process more efficient.

Compatibility With Advanced Cutting Tools

The remanufacturing process can improve the grinder’s ability to handle advanced cutting tool technology, allowing businesses to explore new machining options and remain industry leaders.

Choosing the Right Remanufacturing Partner for Your Okuma Grinder

Choosing the right partner to remanufacture your Okuma grinder is crucial. GCH Machinery excels with its experience, technical skills, dedication to quality, and continuous support, making it a top choice for precision machining businesses.

- Experience and Expertise: GCH Machinery has a proven track record of successfully remanufacturing various Okuma models, ensuring each project is completed with the right expertise and insight specific to the machine’s design and functionality.

- Technical Capabilities: The remanufacturing process requires specialized equipment and expert knowledge, which GCH Machinery has invested in, ensuring we have the resources to conduct a thorough rebuild of your Okuma grinder.

- Genuine Parts and Quality Control: The use of genuine Okuma parts or their OEM-approved equivalents, along with strict quality control procedures, guarantees a level of quality and reliability that aligns with Okuma’s own standards.

- Warranty and Support: GCH offers a 2-year warranty on the main mechanical components and a 1-year warranty on the complete machine. Our commitment to support doesn’t end at the sale; we are invested in the ongoing success of your operation.

Invest in Precision, Invest in Remanufacturing

Reinvesting in precision via cost-effective grinder remanufacturing is key for businesses aiming to stay ahead and eco-friendly. GCH Machinery’s dedication to quality, expertise and customer support makes the remanufactured Okuma grinder more than a machine—it’s a symbol of the lasting partnership between your business and advanced technology.

If you need an Okuma grinder rebuild or remanufacture, now’s the perfect time. Contact GCH Machinery to discuss how we can customize the remanufacturing process to suit your needs and improve your operations’ precision.