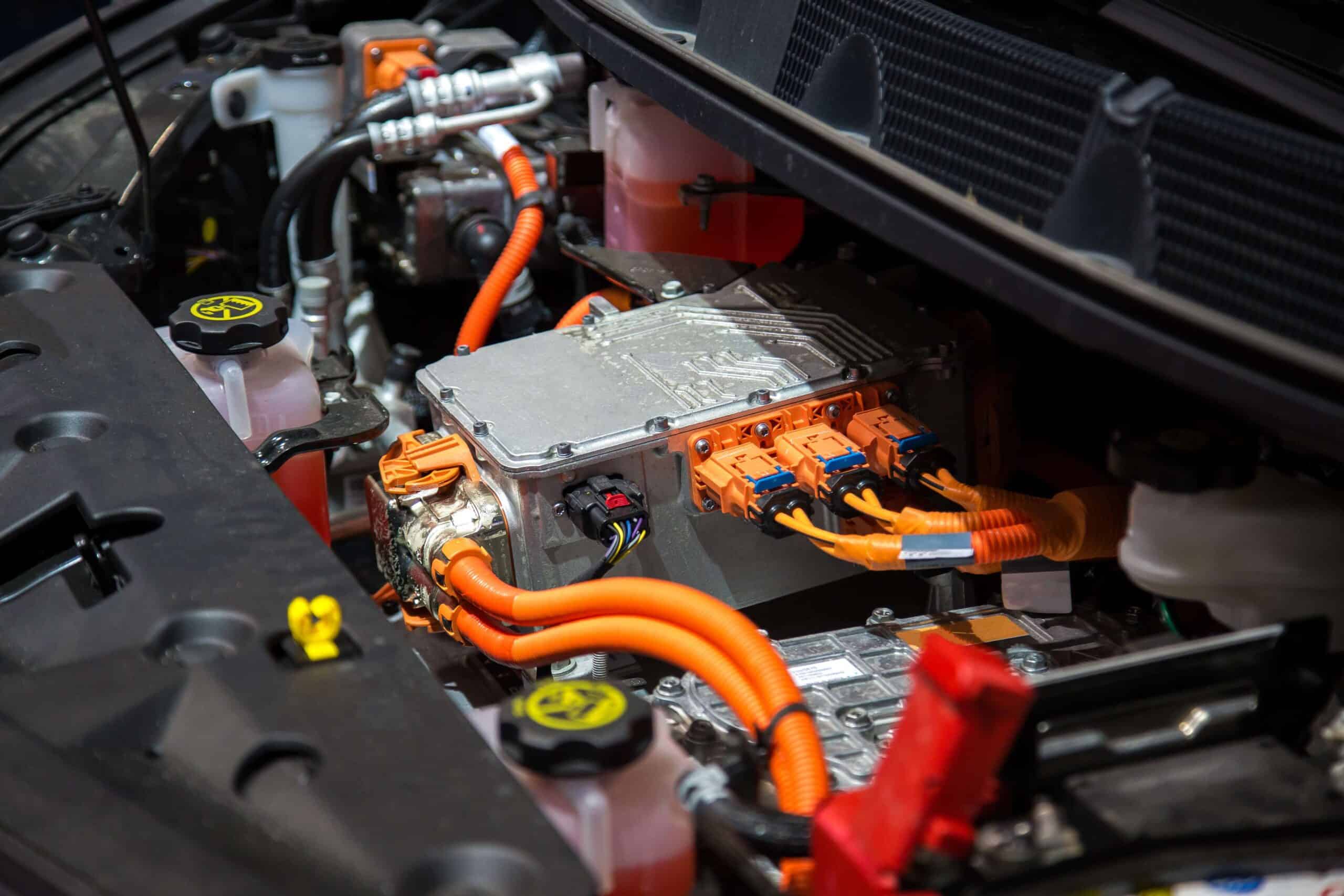

As the world is going green and governments are looking to ban the sale of fuel-based vehicles around the globe, automotive manufacturers are switching from building internal combustion engine (ICE) vehicles to electric ones. This has brought about higher demands for EV parts manufacturing, especially as consumers are inclined to go for environmentally friendly technologies.

Grinding Machines for EV Parts Manufacturing

The manufacturing processes of EV parts require accuracy, precision and specialized equipment, such as grinding machines that are used to shape and finish complex metal parts. Even though the current grinding machine technology used in the auto industry is well suited for traditional internal combustion engines, grinders for EV parts require some reengineering.

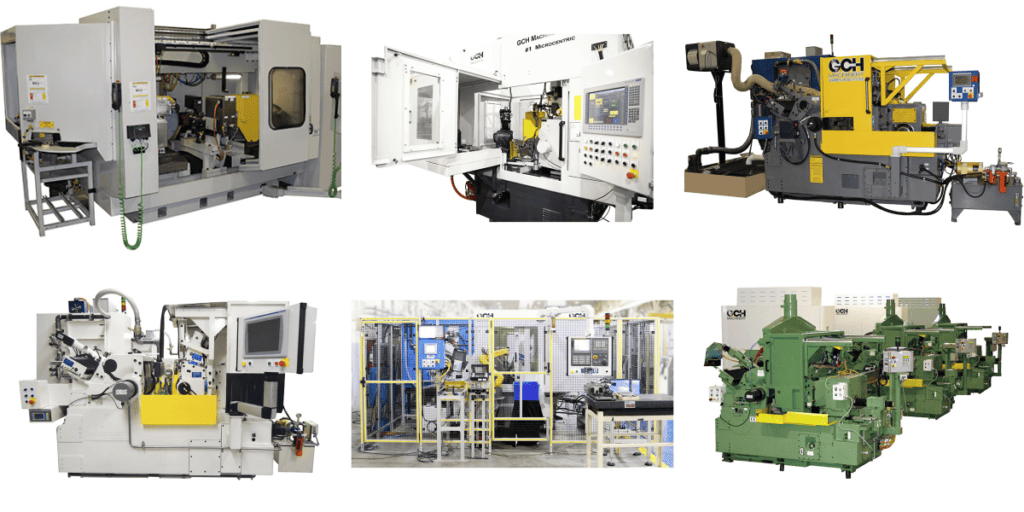

Already holding close tolerances, present grinding machines used in the auto industry for internal combustion engines have the flexibility of evolving into an efficient and precise producer of EV parts. Through grinder remanufacturing and or reengineering, the addition of new controls and specialized tooling convert and upgrade machines to the new EV part specifications.

The rise in the demand for EV parts may strain the capacity of traditional grinding machines, which will undoubtedly delay production.

The best way to address these limitations is by remanufacturing and upgrading grinding machines to meet the requirements of EV parts manufacturing.

Remanufacturing and Upgrading Existing Grinding Machines

Remanufacturing and upgrading grinders to meet the requirements of EV parts manufacturing can be done through a variety of methods:

Assessing the Current Capabilities and Limitations of Existing Machines

This is the first step to be carried out whenever we think about remanufacturing services. Evaluating the present performance based on its accuracy, efficiency, and ability to handle different materials is the only way to determine what needs to be upgraded. After a thorough assessment is conducted, the results can then be compared with the requirements of the EV parts that need to be manufactured.

Identifying Necessary Modifications and Upgrades to Improve Efficiency

Based on the assessment results, necessary upgrades and modifications can then be identified to improve the machine’s performance and ensure it is suited for EV parts manufacturing.

Implementing Modifications and Upgrades

Once the areas that need to be modified and upgraded have been identified, the next step is to implement them to the machine. At GCH Machinery, we retooled an old machine that was not capable of holding size. As a result, the machine was able to be put into operation for two brand-new EV parts.

Adding Features for Green Manufacturing/Reducing Carbon Footprint

Adding some green manufacturing features is also important to reduce the machine’s carbon footprint. Some of the new features that can be added to the machines are high-efficiency motors and a mist-containment system which helps reduce the environmental impact of the machine and overall supports the automaker’s environmentally friendly manufacturing initiative.

And most importantly, at GCH Machinery, our grinder rebuilds meet the global safety certification agency’s safety needs.

Reengineering New Grinding Machines for EV Parts Manufacturing

GCH Machinery engineers work with clients to develop custom grinding machines. Processes are developed based upon the client’s part specifications and manufacturing requirements. Our success working with companies from various industries such as automotive, aerospace, medical, energy and others have contributed to our systematic approach in developing specifications and requirements for new machines. Those assets give GCH an edge when developing grinders specifications and requirements for new industries such as EV parts.

Developing Specifications and Requirements for New Machines.

EV parts manufacturing process is different from ICE. Some of its specifications are higher precision, accuracy, etc. Hence, at GCH Machinery, our industry experts take this into consideration while building grinding machines for EV parts. This will ensure that the new machines adequately meet the needs of the EV parts manufacturing process.

Collaborating with Engineers and Manufacturers to Create Custom Grinding Machines

After developing the specifications for the new machines, it is crucial to collaborate with engineers and manufacturers to design machines that will meet those needs.

Testing and Refining Prototypes to Ensure Optimal Performance

After the new machines have been successfully remanufactured, testing prototypes and ensuring their performance meets expectations before putting them into production is important. Thorough testing will quickly help in identifying areas of adjustment before they are put into use.

Implementing New Grinding Machines in Production

For a successful implementation of new grinding machines in production, it is crucial to do the following:

Training Production Staff on the Use and Maintenance of New Machines

It is crucial to train the production staff on using the new machines. This is the best way to ensure they use the machines safely and efficiently. It is also pertinent that the staff are trained on the new machines’ maintenance procedures to ensure optimal performance and extend their lifespan.

Integrating New Machines into the Production Workflow

The new machines should be integrated into the production workflow in a way that can improve efficiency. It is also worthy of mention that the new machines are adaptable to the existing equipment used in the production process.

Monitoring and Adjusting Machine Performance as Needed

It is not enough to integrate the new machines; it is also essential to monitor their performance and make necessary adjustments as required to ensure smooth production.

Also Read: Grinder Remanufacturing for the Automotive Industry

GCH Machinery’s Successful Projects for the EV Industry

At GCH Machinery, we are always looking forward to the best ways to serve the EV industry. We’ve successfully:

- Rebuilt a grinding machine for an EV company to better improve the production of transmission parts

- Redesigned and supplied a turn-key grinding system with retrofitted machines for EV industries.

At GCH Machinery, our remanufacturing and reengineering processes starts from working with you to identify necessary modifications and upgrades in your old machines to determining the best option to suit your needs and budget until we are sure the new machines are properly integrated into production.

As the world is going green, investing in remanufacturing and reengineering of grinding machines for EV parts manufacturing is the wisest decision any EV company keen on maximizing its production and becoming more sustainable can make. To learn more, contact us today.