We’ve written before about knowing when to have your grinder remanufactured to keep it operating like new.

But one hidden advantage of rebuilt grinders is that remanufacturing can actually make your grinder better than new, offering improved productivity beyond what your machine originally provided.

Boosting productivity doesn’t happen by accident. It’s the result of a carefully planned and executed remanufacturing process designed and completed by experts who understand your needs and have an inside-and-out knowledge of grinders and grinding equipment.

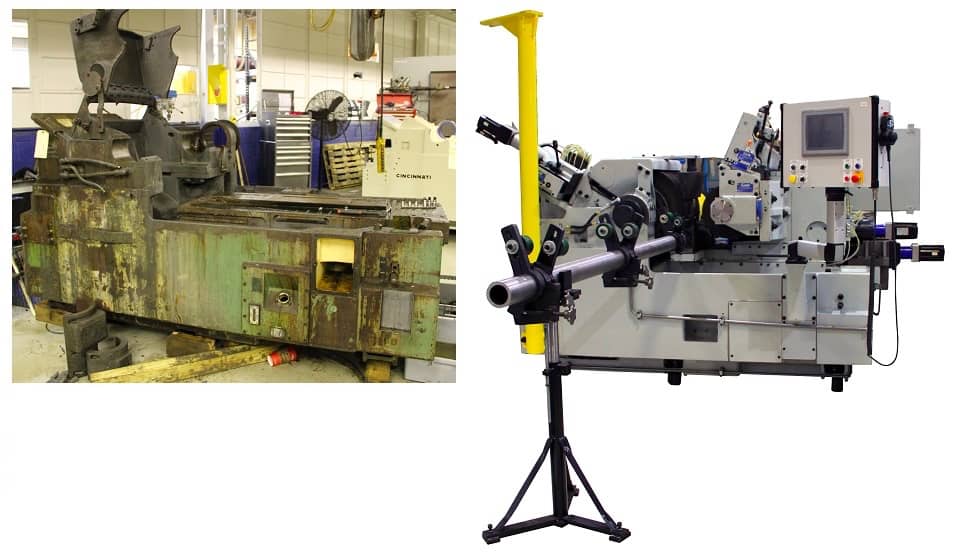

Remanufactured 20M Cincinnati centerless grinder, before (at left) and after.

Our remanufacturing process is a good example of the expertise and attention to detail required to generate productivity improvements. We begin by completely disassembling your machine to bare casting and then removing all hoses and components, saving nothing for re-use. Discarded components include:

- Hydraulic

- Pneumatic

- Lube

- Coolant

We then turn our attention to the cast components and base machine by:

- Sandblasting all cast components and base machines

- Priming all cast components and base machine

- Painting all components and base machine to customer specifications

Our next focus is to bring your grinder completely into the 21st century. We remanufacture all mechanicals to currently accepted tolerances by hand scraping the slide and/or adding new technologies. We also wire and add all new, cutting-edge PLC/CNC controllers to meet your specifications.

340-20 Cincinnati centerless grinder remanufactured, before (above) and after (at right).

As with the previous steps, our subsequent tasks all center on ensuring your grinder meets your specifications and requirements:

- Adding all-new plumbing, hydraulics, pneumatics, lube, and coolant components

- Supplying and designing all tooling required to process the customer parts

- Providing runoffs and qualifying the machine to your specific Cpk/Ppk requirements

GCH Machinery can also fully turnkey any grinding machine with automation and gaging to meet even your most demanding part processing requirements. This phase can include:

- Robots

- Gantries

- In-process gaging

- Post-process gaging

- Rotary dresser spindles

- Plunge dresser spindles

- Work holding

- Safety integration

- Partial/full enclosures

- Coolant systems

- Mist collection

Our grinder remanufacturing process is involved and time-consuming, with a very clear attention to detail and a dedicated commitment to achieving your part processing goals. We take steps that less-reputable rebuilders might gloss over or avoid, simply to improve their own bottom lines.

But at GCH Machinery, our customers’ needs come first, and we routinely go the extra mile to ensure you achieve the productivity improvements your operation demands.

Contact us today to put our dedication and expertise to work for you.

Not ready to commit to a full remanufacturing project? Tune back in next month when we discuss productivity-boosting automation improvements that we can implement for your machines.