Besly Double-Disc Grinder Services

“The Besly grinder has proven itself to be all that we expect of it, and is doing the work in the most excellent fashion.”

— Anonymous quote appearing in a 1909 print advertisement. Courtesy of vintagemachinery.org.

Although the words fashion and grinder are rarely associated, Besly grinders boast a reputation as one of the finest grinder brands ever established. Perhaps lesser known than its double-disc cousin, the Gardner grinder, Besly boasts a long history in grinder manufacture. The Charles H. Besly Company, home of the Besly grinder, built the first disc-grinding machine in the U.S. in 1891. [Side note: That original grinder is now displayed at the Henry Ford Museum in Greenfield Village in Dearborn, Michigan.]

Vertical and Horizontal Grinders

Charles Besly, who started the operation with one employee, established the Charles H. Besly Company in 1891, in Beloit, Wisconsin. Frederick Gardner later joined the company and developed the disc-grinding machine. As you may know, Mr. Gardner established his own grinding company in 1905, after serving as superintendent and general manager of the Besly Company for ten years. The Besly Company went on to produce both horizontal and vertical double-disc grinders as well as vertical rotary surface grinders.

Double-disc grinders grind two sides of a workpiece simultaneously. Double-disc grinders hold remarkable standards for parallelism, flatness and size in high-volume production environments. Because the machine grinds two sides of the part at the same time, you’ll save on handling costs and grind time. Double-disc grinders boast high productivity rates, with streams of parts flowing rapidly through the machines.

Besly grinders are commonly used for:

- Blades and knives

- Conrods

- Cutters and dies

- Extrusions

- Gages

- Laminations

- Medical devices

- Part blanks

- Rings

- Shims/spaces/washers

- Stamping

- Substrates

- Valves

- Valve plates

Known for their rugged and rigid construction and “old school” great vibration-dampening cast iron bases, Besly grinders are ideal candidates for remanufacturing. Your Besly grinder can be updated with modern slides, dressers, feed systems and a host of other upgrades. A grinder remanufacture will bring the machine back to OEM or better-than-OEM standards.

Extensive Besly Grinder Expertise

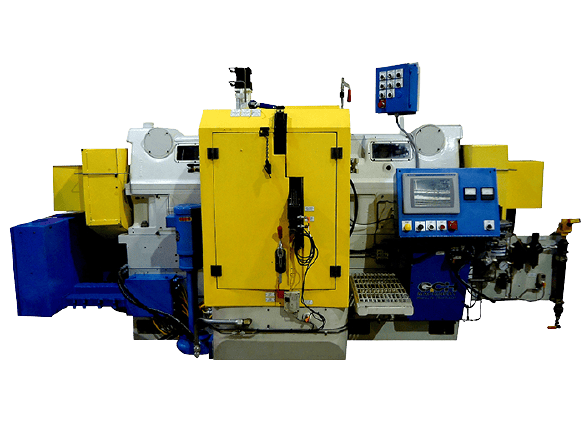

GCH Machinery has remanufactured these popular Besly grinder models and others:

- Besly DV2

- Besly DH2-23

- Besly DH4-30

- Besly DH6-30

- Besly SCV2-23

- Besly V6000

GCH Machinery is the world leader when it comes to Besly grinder remanufacture. We adhere to stringent quality standards that are tested and documented at every point of the manufacturing process. GCH Machinery is the only grinder manufacturer that has designed and built test stands to duplicate actual running conditions for every major machine assembly. Your components will be tested for a minimum of eight (8) hours before they are mounted on your respective machine base.

Have a Besly grinder that needs help? Contact GCH Machinery.

Contact Us

Request for Quote

Fields marked with an asterisk are required.